CNC (Computer Numerical Control) 技術是一種現代化的控制技術,利用電腦控制和監測機器工具的運動和操作,被廣泛應用於製造業各個領域。在工業擠型過程中,CNC技術扮演了重要的角色,能夠實現高精度、高效率的生產。

工業擠型是一種常見的金屬加工方式,將鋁材等金屬加熱至柔軟狀態,然後通過壓力將其擠製成所需形狀的產品。CNC技術通過精確的控制機器工具的運動軌跡和力度,能夠實現複雜的擠型加工,使得產品的尺寸和形狀能夠精確控制,且生產過程中的浪費減少。因此,CNC技術在工業擠型領域中得到了廣泛應用。

除了CNC技術外,陽極處理也是工業擠型過程中不可或缺的一個步驟。陽極處理是通過在鋁材表面形成一層氧化膜,使其具有更好的耐腐蝕性、耐磨性和耐熱性。這一處理過程不僅能夠提高產品的品質和壽命,還能美化產品的外觀。陽極處理通過控制處理時間、電流密度和溫度等參數,能夠實現對鋁材表面氧化層的厚度和顏色的精確控制。

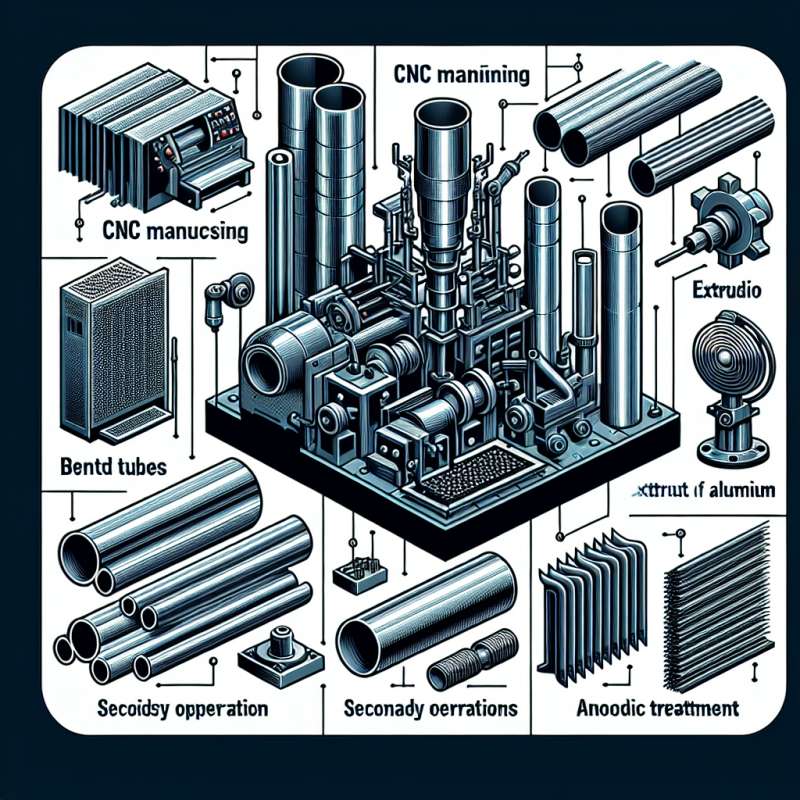

在工業擠型過程中,除了CNC技術和陽極處理外,工件的二次加工也是一個重要的環節。二次加工是指在工業擠型完成後,對產品進行進一步的加工和處理,以滿足不同客戶的需求。例如,對鋁管進行彎管加工來製作特定形狀的管路,或者對散熱片進行切割和打孔來提高散熱效果等。二次加工的過程中,也需要借助CNC技術進行精確的操作和控制。

綜上所述,CNC技術在工業擠型中的應用不僅能夠提高生產效率和產品的精度,還能夠實現複雜形狀和尺寸的擠型加工。陽極處理和二次加工則能夠提高產品的質量和功能。隨著科技的進步和工業擠型技術的不斷發展,相信CNC技術將在工業擠型中扮演更加關鍵的角色。

關鍵字: CNC, Industrial Extrusion, Anodizing

標題: Application of CNC Technology in Industrial Extrusion

CNC (Computer Numerical Control) technology is a modern control method that utilizes computer systems to monitor and control the movements and operations of machine tools. It has been widely adopted in various manufacturing industries. In the process of industrial extrusion, CNC technology plays a crucial role in achieving high precision and efficiency in production.

Industrial extrusion is a common metalworking technique that involves heating materials such as aluminum to a malleable state and then forcing them through a die to obtain the desired shape. With precise control over the movement and force of machine tools, CNC technology enables complex extrusion processes, ensuring accurate control of product dimensions and shapes while reducing waste. Therefore, CNC technology has found extensive applications in the field of industrial extrusion.

In addition to CNC technology, anodizing is also an essential step in the process of industrial extrusion. Anodizing involves forming an oxide layer on the surface of aluminum to enhance its corrosion resistance, wear resistance, and heat resistance. This treatment not only improves the quality and durability of products but also enhances their appearance. By controlling parameters such as treatment time, current density, and temperature, anodizing enables precise control over the thickness and color of the oxide layer on aluminum surfaces.

Apart from CNC technology and anodizing, secondary machining of extruded components is also critical. Secondary machining refers to further processing and treatment of products after the extrusion process to meet specific customer requirements. For example, bending aluminum tubes to create customized pipelines or cutting and perforating heat sinks to improve heat dissipation efficiency. CNC technology is often employed during secondary machining processes to ensure precise operations and control.

To sum up, the application of CNC technology in industrial extrusion not only improves production efficiency and product precision but also facilitates the complex shaping of various sizes and shapes. Anodizing and secondary machining further enhance the quality and functionality of extruded products. With the continuous development of technology and the advancement of industrial extrusion techniques, CNC technology is expected to play an increasingly crucial role in this field.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)